Close

Perfect support for testing models and production code

AUTOSAR, short for Automotive Open System Architecture, is a standardized software architecture framework that enhances efficiency, scalability, and reusability of software in the automotive industry. It provides guidelines and specifications for developing automotive software components that integrate and collaborate across different ECUs.

By promoting a modular and layered approach, AUTOSAR manages complexity and allows for software functions to be separated from hardware, enabling flexibility and interoperability.

With standardized interfaces and communication protocols, AUTOSAR promotes compatibility among automotive systems, facilitating software reuse across vehicle models and generations.

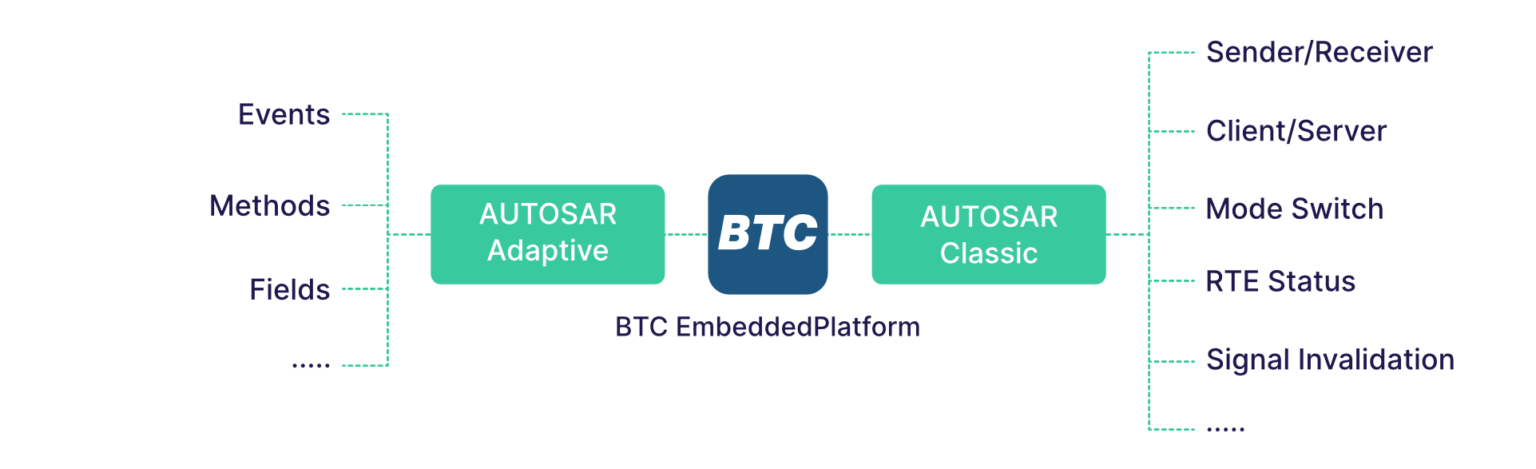

AUTOSAR Classic and AUTOSAR Adaptive platforms, while sharing the same overarching aim of standardizing automotive software, cater to different requirements within the automotive industry.

AUTOSAR Classic is designed primarily for hard real-time control systems, such as engine control and brake systems, which require deterministic behavior and low latency responses.

On the other hand, the AUTOSAR Adaptive platform is targeted at high-performance computing systems, typically found in infotainment, telematics, and advanced driver-assistance systems. The Adaptive platform leverages dynamic software updates, service-oriented communication and supports the POSIX operating system, making it suitable for complex and highly interactive applications.

This basically means that Adaptive is not meant as a replacement for the Classic platform, we can expect both standards to coexist in the future.

Autosar offers numerous benefits, but it also presents unique challenges in terms of testing software at both the Simulink model level and production code level.

Identifying the test interface

Autosar offers numerous benefits, but it also presents unique challenges in terms of testing software at both the Simulink model level and production code level.

Mapping of model and code elements

In a model-based development process, tests are necessary at both the model and code levels. While AUTOSAR interfaces are defined at the code level, they don’t exist at the model level. So, how do we connect elements of a Simulink model and the AUTOSAR language? The code generator accomplishes this task, and depending on the tool used (e.g., dSPACE TargetLink or Mathworks EmbeddedCoder), the model architecture for the same AUTOSAR component can vary significantly. The testing tool should automatically understand this mapping, allowing for seamless test execution at both levels.

Stubbing for SIL testing

For testing AUTOSAR Software Components (or AUTOSAR Adaptive Applications) on the production code level (SIL) we obviously need to compile the code. The challenge: these components are even less self-contained than what we typically see in non-AUTOSAR applications. A lot of dependencies towards the RTE (Classic) or ARA (Adaptive) need to be stubbed in order to compile and test individual units.

BTC Embedded Systems is a member in the AUTOSAR consortium, bringing years of experience in supporting the platform. With BTC EmbeddedTester, AUTOSAR Classic and AUTOSAR Adaptive are fully supported for dSPACE TargetLink and Mathworks Embedded Coder.

The tool automatically analyzes and comprehends the AUTOSAR architecture, extracting a corresponding test interface. For instance, a client/server call with a “Get” semantic is interpreted as an input signal for the test architecture. Moreover, BTC EmbeddedTester understands the mapping of model elements and code elements, enabling seamless execution of test cases on both model and code level without the need for manual test harness preparation. Additionally, the tool ensures that all external references are properly stubbed, either by utilizing stub implementations from the code generator or by adding missing elements itself.

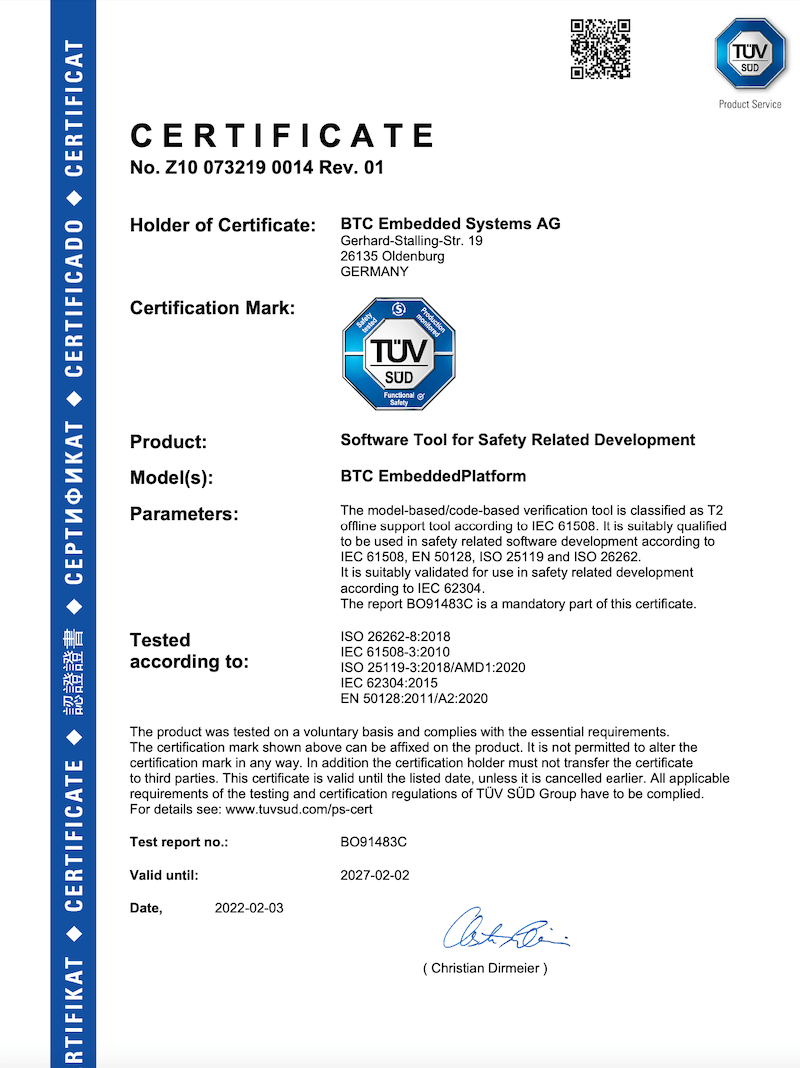

BTC EmbeddedPlatform (incl. BTC EmbeddedTester BASE, BTC EmbeddedTester, BTC EmbeddedSpecifier and BTC EmbeddedValidator) has been certified by German TÜV Süd as fit for usage in safety critical software development projects.

The certificate addresses different standards including IEC 61508-3:3010, ISO 26262, EN 50128, IEC 62304 as well as ISO 25119.

For the automotive standard ISO 26262, we have been certified with the highest tool confidence level TCL and the certificate is valid for all ASIL levels including ASIL D.

We provide the certificate and the corresponding report to our customers free of charge upon request, which almost eliminates any effort for tool qualification measures on the customer side.

Nabile Khoury

Paris, France

Nabile Khoury

Paris, France

Smart test generation for an ISO 26262 certified and fully automated Back-to-Back Test

We provide intelligent and automated test solutions which enable our customers to deal with the growing complexity of embedded software while achieving high quality in compliance with the ISO 26262 standard.

Copyright © 2025 BTC Embedded Systems